TEN AEM Particle Counter

From 2021 the particle counter will be introduced in different countries. The exhaust emissions of Euro 5 and 6 diesel vehicles must then be measured with this new tester. What is involved? We are happy to explain it to you!

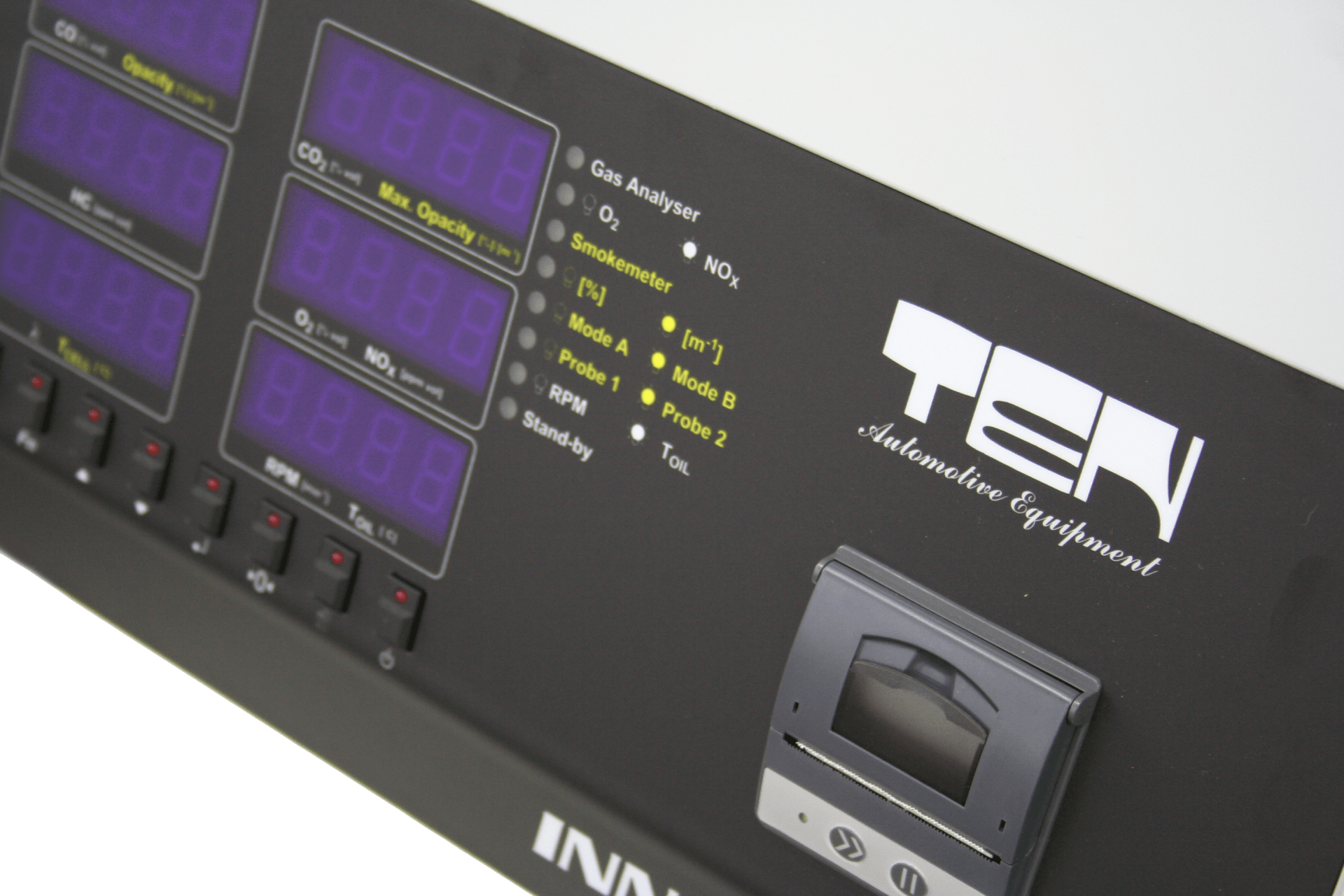

Test Equipment Nederland BV (TEN) has been developing and producing exhaust gas emission equipment since 1985. We do this with a group of enthusiastic colleagues in Baambrugge, located in the area of Amsterdam. Every year we produce between 5.000 and 6.000 emission testers, which are largely exported. TEN has an international dealer network that is responsible for local sales and aftersales of TEN workshop equipment.

What is a particle counter?

Opacity meters have become more accurate over the years, but in particular with modern diesel vehicles where soot emissions are very low, the smoke meter is insufficient.

The emission of a properly functioning Euro 6 diesel engine is, partly due to the particle filter, very low. The soot particles that are emitted are very small, on average around 80 nm. They are not visible with the human eye. A particle counter (or PN meter) can detect these particles and thus indicate that the diesel vehicle still meets the regulations.

This particle counter is very advanced and has state-of-the-art techniques that are capable of detecting the small nanoparticles. The particles are indicated in # / cm3 (particles per cubic cm). A diesel engine with a properly functioning particle filter emits less than 20,000 particles. A diesel engine with a defective filter can emit millions of particles!

How does a particle counter work?

The current diesel exhaust measurement as we know it in the MOT, is performed with a free acceleration. The accelerator pedal must be pressed to the maximum and this is how the maximum smoke emission is measured. Certainly in the early years of diesel exhaust measurement, this caused many annoyances and problems. With the new particle counter, this free acceleration is a thing of the past. A particle counter measures at idle speed and will therefore be friendlier to use. The engine will of course have to be at operating temperature before the measurement, in order to guarantee correct operation of the particle filter. A separate speed measurement will not be necessary.

The TEN AEM particle counter!

After switching on the TEN AEM particle counter, the tester performs a system test, the Initialization. During this test you will hear that the various components are activated. After Initialization, the AEM will start to heat up the internal inlet gas heater. From a 'cold' start, the warm-up time is approximately eight minutes. However, if the heating is already up to temperature, the heating time will be dynamically calculated and adjusted.

In the main menu of the AEM you can select the different menu items using the ▲ and ▼ keys. In this main menu the following items are available MOT Measurement, Standard Measurement, Leak Test, System Info, Service Menu. Below you will see a few items briefly explained.

APK Measurement Official MOT measurement that is carried out in accordance with the requirements of the RDW, which from 2021 apply to diesel vehicles that are fitted with a diesel particulate filter (DPF) as standard by the manufacturer.

DET vehicle PN limit value

Before 01-01-2015 1000 k # / cm3

DET stands for Date of First Admission of the vehicle. This therefore concerns the vehicles registered before 2015 (normally Euro 5A and 5B vehicles).

DET vehicle PN limit value

After 12/31/2014 250 k # / cm3

These are vehicles registered after December 31, 2014 (normally Euro 5B and Euro 6)

After choosing the appropriate limits, the tester will begin automatic zero calibration and you can insert the heated recording probe into the exhaust. After stabilizing for 15 seconds, the AEM automatically starts the emission measurement or registration. The registration period also lasts 15 seconds. The AEM automatically calculates the average of all readings and displays the result to you. Depending on the result, the message follows: Test passed or Test failed!

During stabilization or measurement, the AEM can measure such a high particle concentration that exceeds twice the maximum allowed concentration! This is probably due to a broken particulate filter or other special condition of the vehicle (e.g. regeneration). The measurement is automatically aborted to prevent contamination of the tester. The result screen will indicate that the test has failed. After all, the test has not been fully completed.

The above software is based on Dutch regulations and can be adjusted if necessary.

Standard measurement

Continuous measurement for various test purposes. Pre-MOT, or just to detect a leak in the exhaust system. After a repair or forced regeneration of the DPF. The standard measurement takes a maximum of 900 seconds or 15 minutes. You will see the time display decreasing per second. As soon as the time display is at 0, a zero point calibration is performed automatically again. You can then measure 900 seconds again.

Leak test

Test to check the complete flow system of the AEM, from the sample probe to the pump, for gas tightness. During the leak test, the recording probe is closed and a vacuum is created by the pump. The leakage must not exceed 60 hPa during the 15 second test. Leak-tightness is checked monthly or can be carried out manually at any time through the main menu.

Features

- Heated recording probe

- Communication via: USB, RS232 and Bluetooth

- Stabilized measuring chamber temperature

- Automatic flow control

- Automatic filter control

- Automatic zeroing with HEPA filter

Specifications TEN AEM

| Power input | 220/240 Volt |

| Frequency | 50 Hz |

| Max Power | < 100 W |

| Display | OLED |

| Particle size | 80 Nm |

| Measuring range | 5.000 - 5.000.000 #/cm3 |

| Measuring accuracy | 25.0 |

| Response time | < 15 sec |

| Measuring frequency | 2 Hz |

| Weight approx. | 8 kg |

| Temperature range | 5 - 40 °C |